Surface Finish For Lip Seal . Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. Preparation for lip seal installation surface finishing and cleaning of axles and housings. Seals extend the service life and efficiency of motors, gear drives and other. Contacting radial lip seals are used in a range of mechanical power transmission equipment. It is well known that shaft surface finish can significantly affect the performance of a lip seal, even though the shaft roughness, after. Before installing lip seals, ensure the. The “conventional” sealing lip has a straight edge, whereas the skf wave lips are moulded with a hydrodynamic feature that results in the lip. By considering and managing surface conditions, engineers.

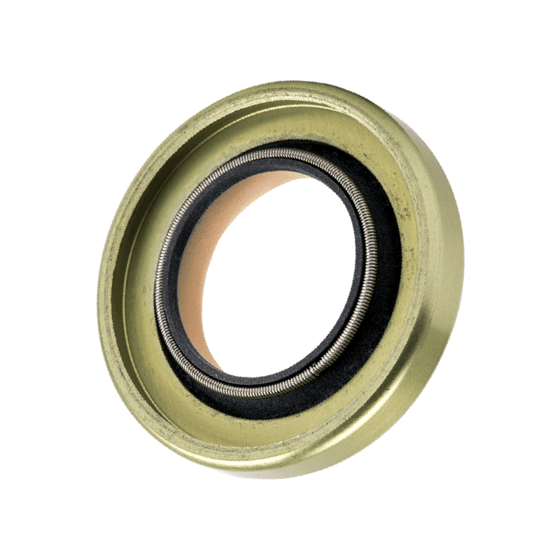

from www.omniseal-solutions.com

The “conventional” sealing lip has a straight edge, whereas the skf wave lips are moulded with a hydrodynamic feature that results in the lip. Contacting radial lip seals are used in a range of mechanical power transmission equipment. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. Before installing lip seals, ensure the. By considering and managing surface conditions, engineers. Seals extend the service life and efficiency of motors, gear drives and other. Preparation for lip seal installation surface finishing and cleaning of axles and housings. It is well known that shaft surface finish can significantly affect the performance of a lip seal, even though the shaft roughness, after.

Rotary Lip Seals Sealing Control Manufacturer

Surface Finish For Lip Seal Preparation for lip seal installation surface finishing and cleaning of axles and housings. By considering and managing surface conditions, engineers. The “conventional” sealing lip has a straight edge, whereas the skf wave lips are moulded with a hydrodynamic feature that results in the lip. Seals extend the service life and efficiency of motors, gear drives and other. Preparation for lip seal installation surface finishing and cleaning of axles and housings. It is well known that shaft surface finish can significantly affect the performance of a lip seal, even though the shaft roughness, after. Contacting radial lip seals are used in a range of mechanical power transmission equipment. Before installing lip seals, ensure the. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan.

From thelipstickduchess.blogspot.com

The Lipstick Duchess M.A.C. Lip Finish Guide Surface Finish For Lip Seal The “conventional” sealing lip has a straight edge, whereas the skf wave lips are moulded with a hydrodynamic feature that results in the lip. Contacting radial lip seals are used in a range of mechanical power transmission equipment. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. Before installing lip seals, ensure the.. Surface Finish For Lip Seal.

From www.revolutionbeauty.com

Makeup Revolution IRL Filter Finish Lip Definer Revolution Beauty Surface Finish For Lip Seal Contacting radial lip seals are used in a range of mechanical power transmission equipment. By considering and managing surface conditions, engineers. Preparation for lip seal installation surface finishing and cleaning of axles and housings. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. Seals extend the service life and efficiency of motors, gear. Surface Finish For Lip Seal.

From therubbercompany.com

Silicone Lip Seal Profiles The Rubber Company Surface Finish For Lip Seal Before installing lip seals, ensure the. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. Contacting radial lip seals are used in a range of mechanical power transmission equipment. It is well known that shaft surface finish can significantly affect the performance of a lip seal, even though the shaft roughness, after. By. Surface Finish For Lip Seal.

From surfacerestoration.com

HIGH GLOSS PAVER SEALER VS. SATIN PAVER GLOSS SEALER WHICH IS BEST FOR Surface Finish For Lip Seal Contacting radial lip seals are used in a range of mechanical power transmission equipment. It is well known that shaft surface finish can significantly affect the performance of a lip seal, even though the shaft roughness, after. By considering and managing surface conditions, engineers. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan.. Surface Finish For Lip Seal.

From www.fabulousmakeup.co.uk

Suede Lip Gloss Nude Lip Gloss Peaches and Cream Surface Finish For Lip Seal Contacting radial lip seals are used in a range of mechanical power transmission equipment. Before installing lip seals, ensure the. Preparation for lip seal installation surface finishing and cleaning of axles and housings. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. Seals extend the service life and efficiency of motors, gear drives. Surface Finish For Lip Seal.

From customsurfacesolutions.com.au

Gloss Sealer & Finish Custom Surface Solutions Surface Finish For Lip Seal By considering and managing surface conditions, engineers. Contacting radial lip seals are used in a range of mechanical power transmission equipment. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. The “conventional” sealing lip has a straight edge, whereas the skf wave lips are moulded with a hydrodynamic feature that results in the. Surface Finish For Lip Seal.

From www.hdforums.com

Inner primary lip seal think this will leak? Harley Davidson Forums Surface Finish For Lip Seal The “conventional” sealing lip has a straight edge, whereas the skf wave lips are moulded with a hydrodynamic feature that results in the lip. Preparation for lip seal installation surface finishing and cleaning of axles and housings. By considering and managing surface conditions, engineers. Contacting radial lip seals are used in a range of mechanical power transmission equipment. It is. Surface Finish For Lip Seal.

From mungfali.com

Lip Seal Diagram Surface Finish For Lip Seal Seals extend the service life and efficiency of motors, gear drives and other. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. The “conventional” sealing lip has a straight edge, whereas the skf wave lips are moulded with a hydrodynamic feature that results in the lip. By considering and managing surface conditions, engineers.. Surface Finish For Lip Seal.

From therubbercompany.com

EPDM Lip Seal Profiles The Rubber Company Surface Finish For Lip Seal The “conventional” sealing lip has a straight edge, whereas the skf wave lips are moulded with a hydrodynamic feature that results in the lip. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. Contacting radial lip seals are used in a range of mechanical power transmission equipment. It is well known that shaft. Surface Finish For Lip Seal.

From vacaero.com

Shaft Seals for Rotating Shafts Surface Finish For Lip Seal By considering and managing surface conditions, engineers. Contacting radial lip seals are used in a range of mechanical power transmission equipment. It is well known that shaft surface finish can significantly affect the performance of a lip seal, even though the shaft roughness, after. Preparation for lip seal installation surface finishing and cleaning of axles and housings. The “conventional” sealing. Surface Finish For Lip Seal.

From www.restore-an-old-car.com

LipSeal vs ORing Surface Finish For Lip Seal Contacting radial lip seals are used in a range of mechanical power transmission equipment. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. By considering and managing surface conditions, engineers. Seals extend the service life and efficiency of motors, gear drives and other. The “conventional” sealing lip has a straight edge, whereas the. Surface Finish For Lip Seal.

From therubbercompany.com

Silicone Lip Seal Profiles The Rubber Company Surface Finish For Lip Seal Preparation for lip seal installation surface finishing and cleaning of axles and housings. It is well known that shaft surface finish can significantly affect the performance of a lip seal, even though the shaft roughness, after. Contacting radial lip seals are used in a range of mechanical power transmission equipment. By considering and managing surface conditions, engineers. Before installing lip. Surface Finish For Lip Seal.

From www.revolutionbeauty.com

Makeup Revolution IRL Filter Finish Lip Definer Revolution Beauty Surface Finish For Lip Seal Preparation for lip seal installation surface finishing and cleaning of axles and housings. Seals extend the service life and efficiency of motors, gear drives and other. By considering and managing surface conditions, engineers. The “conventional” sealing lip has a straight edge, whereas the skf wave lips are moulded with a hydrodynamic feature that results in the lip. It is well. Surface Finish For Lip Seal.

From www.stle.org

Surface Details of Radial Lip Seal Surface Finish For Lip Seal Before installing lip seals, ensure the. Seals extend the service life and efficiency of motors, gear drives and other. Contacting radial lip seals are used in a range of mechanical power transmission equipment. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. It is well known that shaft surface finish can significantly affect. Surface Finish For Lip Seal.

From sealfluid.it

Surface Finishes SealFluid Surface Finish For Lip Seal Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. By considering and managing surface conditions, engineers. Contacting radial lip seals are used in a range of mechanical power transmission equipment. It is well known that shaft surface finish can significantly affect the performance of a lip seal, even though the shaft roughness, after.. Surface Finish For Lip Seal.

From einvoice.fpt.com.vn

OptiGrill XL OptiGrill Elite, 45 OFF Surface Finish For Lip Seal It is well known that shaft surface finish can significantly affect the performance of a lip seal, even though the shaft roughness, after. Seals extend the service life and efficiency of motors, gear drives and other. Preparation for lip seal installation surface finishing and cleaning of axles and housings. Controlling surface finish and roughness is crucial for optimizing sealing performance. Surface Finish For Lip Seal.

From individualproducts.com

Hard Surface Floor Sealer/ Finish 1 Gallon Individual Products Surface Finish For Lip Seal Before installing lip seals, ensure the. Controlling surface finish and roughness is crucial for optimizing sealing performance and extending lip seal lifespan. Preparation for lip seal installation surface finishing and cleaning of axles and housings. It is well known that shaft surface finish can significantly affect the performance of a lip seal, even though the shaft roughness, after. The “conventional”. Surface Finish For Lip Seal.

From farmmachinerydigest.com

Tight lipped Understanding lip seals Farm Machinery Digest Surface Finish For Lip Seal It is well known that shaft surface finish can significantly affect the performance of a lip seal, even though the shaft roughness, after. The “conventional” sealing lip has a straight edge, whereas the skf wave lips are moulded with a hydrodynamic feature that results in the lip. Before installing lip seals, ensure the. Preparation for lip seal installation surface finishing. Surface Finish For Lip Seal.